Our products

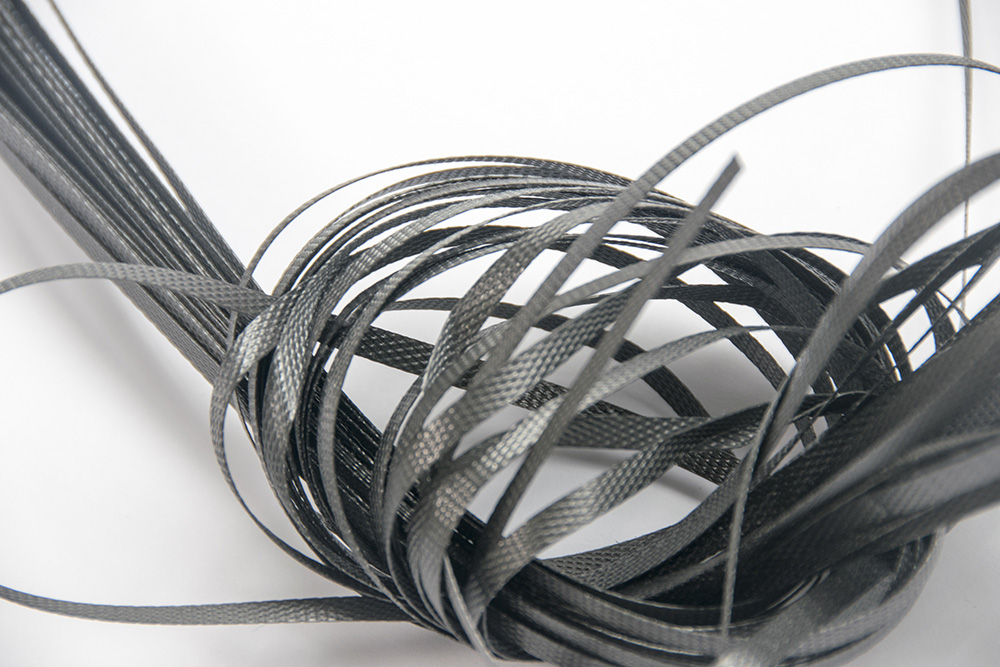

Strapping products

PET strapping, also known as “PET packing belt” and “Polyester strapping”, is made from polyethylene terephthalate, the same material used in water bottles. Our PET strapping is crafted through a series of specific processes and techniques, creating a perfect harmony between high strength and elasticity. PET is formulated to mimic the properties of steel while providing many advantages as a plastic material. It is more elongated and elastic than steel strapped, making it ideal for securely fastening packages over long periods of time, absorbing impacts without breaking.

Compared to steel straps, PET offers increased safety to operators and reduced environmental impact. Additionally, it is an affordable option that never rusts or stains when it comes into contact with water. It is no wonder that PET supplanted steel and PP straps after 2002 and is now the most popular packing belt!

- 50% Cost Savings: PET strapping offers an incredible 50% cost savings compared to steel straps for the same tensile strength. As PET weighs only 1/6 of the steel strap, it is the ideal substitute for packing glass or aluminum ingots. By making the switch to PET strapping, you can save up to 50% of the total packing cost!

- Double Security: With PET strapping, you can enjoy double security. It maintains up to 5% tensile strength for extended periods, while its 5% elongation rate helps cushion the solid exterior impact, ensuring your cargo is safe. Plus, PET straps have a dull edge that won’t damage the load or injure operators.

- Convenient and Efficient: PET straps offer unbeatable convenience and efficiency when it comes to strapping solutions. Plastic strapping tools, such as manual, pneumatic, and battery-powered tools, are easier to use and more affordable than steel strapping tools. Plus, PET straps don’t need to be pre-cut, saving time and improving packing efficiency.

- Weather resistant: PET is an incredibly resilient strapping material, capable of handling temperatures from -100 ℃ to -50 ℃ and withstanding UV degradation for months. Unlike steel, which can quickly degrade in temperature and moisture, PET is practically inert in most storage environments.

BOPP, also known as BOPP tape, packaging tape, etc., is made from biaxially oriented polypropylene film. During the manufacturing process, the film is heated and evenly coated with pressure-sensitive emulsion to form an adhesive layer that ranges from 8 μm to 28 μm. BOPP tape is an indispensable product in the light industry and daily life. BOPP pressure-sensitive adhesive tape is widely used for sealing packaging and boxes. To form a BOPP tape jumbo roll, one side of the BOPP virgin film is treated with high voltage corona to create a rough surface before the glue is applied on the rough side. With different specifications, a slitting machine cuts the jumbo roll into smaller rolls, which is the commonly seen BOPP tape. The main ingredient of Pressure sensitive adhesive emulsion is Butyl acrylate.

Specifications

- The tape has different widths options: 60mm, 48mm, 45mm, 40mm, and 30mm. (measurement unit: millimeter, mm)

- Length options: 50m, 100m, 150m, 200m, 500m. (measurement unit: meter, m)

- Thickness options: 45~55μm (measurement unit: micron, μm)

PP strap (Polypropylene strap) is made from Polypropylene resin, a commonly used plastic material. It’s flexible, lightweight and maintains remarkable break strength. Due to its performance advantage and versatility, the PP strap is widely utilized in various industries. There are different grades of raw Polypropylene resin in the market, among which the best grade for making PP straps is T30S. PP straps come in transparent and non-transparent thin plastic film, making them ideal for multiple applications.

Characteristics:

1. Boasting high elasticity, low density, and excellent impact resistance, these straps are supremely extendable and flexible.

2. It’s versatile and compatible with all types of strapping tools (semi-auto, automatic, and manually operated).

3. PP straps provide strong adhesion, high tensile strength, remarkable lightweight, and corrosion resistance.

4. Additionally, they come in an array of elegant colors, including yellow, white, and black.

5. To top it off, you can even customize them with embossed characters, numbers, or symbols to make them truly unique.

Types of PP straps

1. The virgin Polypropylene granule is transparent, PP strap has the following colour options:

-

-

- Transparent PP strap

- Semi-transparent PP strap

- Colored PP strap

-

2. Depending on the grade of resin, PP strap can be categorized as:

-

-

- Virgin resin PP strap

- Recycled resin PP strap

- Blended resin PP strap

-

3. In terms of the application of PP straps, there are the following types:

-

-

- PP strap for automagical strapping machine

- PP strap for semi-auto strapping machine

- PP strap for manual strapping tools

- PP Cord strap

-

4. If categorized PP straps by compatible PP strapping tools, there are the following types:

-

-

- Machine used PP strap

- Manually handled PP strap

-

Tension parameters