Our products

materials

High-density polyethylene (HDPE) is a granular or white powder plastic material that is non-toxic and tasteless. It has a crystallinity of 80% to 90%, a softening point of 125 to 135°C, and a service temperature of up to 100°C. Compared to low-density polyethylene, HDPE has better hardness, tensile strength, and creep, as well as wear resistance, electrical insulation, toughness, and cold resistance. It also has good chemical stability and is insoluble in any organic solvent at room temperature. HDPE is highly resistant to corrosion from acids, alkalis, and various salts. HDPE film has low permeability to water vapor and air and low water absorption, which means it’s less susceptible to damage from humidity. However, it has poor aging resistance, and its environmental stress cracking resistance is not as good as low-density polyethylene. To improve its deficiency, antioxidants and ultraviolet absorbers should be added to the resin. HDPE film also has a low heat distortion temperature under stress, so it should be applied with care.

High-density polyethylene (HDPE) resins are versatile and can be used to manufacture plastic products through a variety of processes such as injection moulding, extrusion, blow moulding, and rotational moulding. Injection moulding can be used to produce a range of products, including containers, industrial accessories, medical supplies, toys, shells, bottle stoppers, and shields. Blow moulding is suitable for creating different types of hollow containers and ultra-thin films. Extrusion moulding is used to form tubing, stretch tape, strapping, monofilament, and wire and cable sheathing. HDPE can also be used to create architectural decorative panels, shutters, synthetic wood, synthetic paper, synthetic film, and calcium-plastic products.

Low-density polyethylene (LDPE), also referred to as high-pressure polyethylene, is the least dense type of polyethylene resin. It appears milky white, is odorless, tasteless, and non-toxic. It is a waxy particle with a dull surface. LDPE has a density ranging from 0.91g/cm3 to 0.93g/cm3 and exhibits excellent flexibility, extensibility, electrical insulation, transparency, processability, and air permeability. Additionally, LDPE has good chemical stability, alkali resistance, and resistance to most organic solvents.

The scope of application of low-density polyethylene:

Low-density polyethylene, or LDPE, has a wide range of applications, including food packaging for products like seasonings, pastries, sugar, candied fruit, biscuits, milk powder, tea, and fish floss, as well as pharmaceutical packaging for tablets and powders. It is also used for packaging fiber products such as shirts, clothing, and knitted cotton and chemical fiber products, as well as for packaging washing powder, detergent, cosmetics, and other daily chemical products. However, due to the poor mechanical properties of single-layer PE film, it is typically used as the inner layer of composite packaging bags, serving as the heat-sealing substrate for multi-layer composite films.

Ethylene vinyl acetate, in short VAE, which is also called redispersible powder(RDP) is widely used in the construction field. It can be used in the cement mortar, wall putty, EIFS mortar, inner wall mortar, tile bonding mortar and tile seam filling. The extraordinary bonding ability make it a very outstanding bonding additive in the construction. And also improves the coating and spreading rate of the mortar or putty. Also anti cracking, highly improves the strength for the structures.

- Chemical Name: Ethylene vinyl acetate

- Molecular Formula: (C2H4)x(C4H6O2)y

- Moisture /%:≤5

- Residue (Ash) /%: 20-25

- Fineness /mesh: 80-120

- Min Film-forming temperature ℃: 0-5

Application

Tile bonding mortar

Wall putty

Tile grout

Outdoor bonding mortar

EIFS mortar

Spray gun used slurry

Variety:

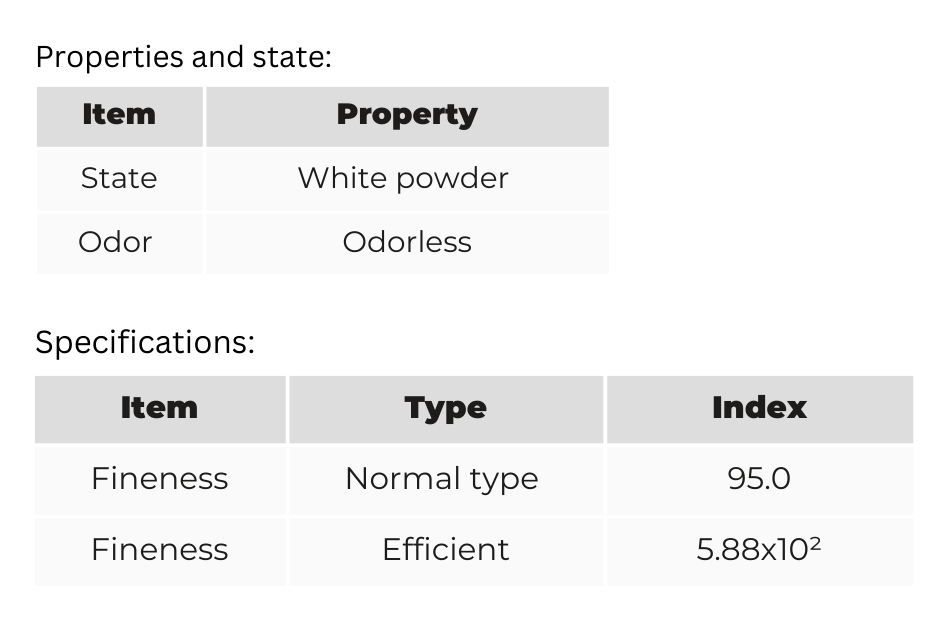

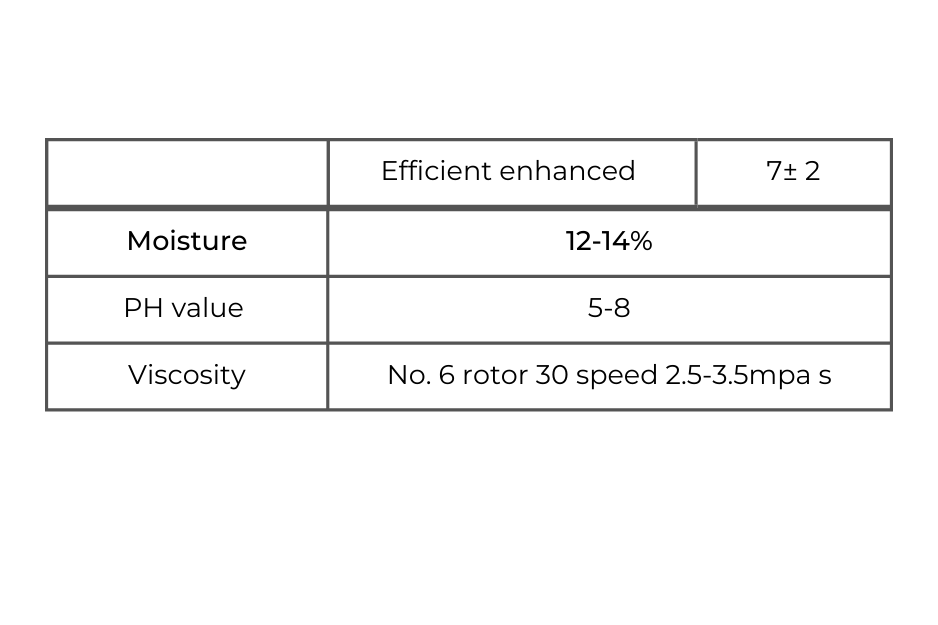

- Ordinary type

- High-efficiency type

- High-efficiency enhanced type

This product is obtained by changing the molecular structure of food starch. It is used in the manufacture of various gypsum board and is suitable for the production of various gypsum (natural, desulfurization, nitryp) and various equipment. Features

-

-

- Strong dispersion and good smoothness;

- strong adhesion, easy to move;

- the film strength is high, the amount is small;

- the dry method is added evenly, and the wet method is added to dissolve quickly;

-

According to the dissolving property, the HPMC can be mainly divided into 2 types. The instant dissolving type, which is widely applied in the detergent industry. Such as shampoo, liquid soap, dish washing detergent, tooth paste, cloth washing detergents, painting, capsule, etc. This type of HPMC can be dissolved into room temperature water, and with high permeability. It can act as thickener, excipient, emulsifier, film-forming agent and dispersant.

These applications requires a very high standard type of HPMC, thus it shall have the following features:

- Shall be dissolvable in room temperature water.

- The solution shall be of high permeability.

- Gain viscosity within 30-60 minutes.

- No stains after storage of several weeks.

The other type is hot dissolving HPMC. This type only have quick dissolving effect under the condition of hot water above 60 ℃. This type of HPMC is mainly used in the construction, ceramic industry, textile industry etc. It can be used as thickener, water retention agent, prolonging the open time, ensures the mortar or wall putty to be anti-drooping, anti-cracking and improves the work-ability. The function of HPMC is very distinct.

- Chemical Name: Hydroxypropyl Methyl cellulose

- Molecular Formula: C36H70O19

- Viscosity/mpa.s:400-200,000

- Moisture /%:≤5

- Residue (Ash) /%: ≤5

- Gel temperature ℃: 62-70

Application

Tile bonding mortar

Wall putty

Tile grout

Outdoor bonding mortar

EIFS mortar

Spray gun used slurry

- Chemical Name: Hydroxyethyl cellulose

- Molecular Formula: (C2H6O2)x

- Viscosity/mpa.s:50,000-200,000

- Moisture /%:≤5

- Residue (Ash) /%: ≤5

- Gel temperature ℃: 62-70

Hydroxyethyl cellulose, HEC in short. Is Mainly used in the paint, coating, drilling fracking, pulp formation for textile, etc. It can be used as dispersant, thickener, emulsifier and stabilizer.

It is white in color and soluble both in hot and cold water. When thoroughly dissolved, the solution is clear and the viscosity can reach peak in about 1 hour. The viscosity is from 400-100000, for different applications.

Application

Coating & Paint

Oil drilling

Textile Production

- Brand Name: YUMING

- Model Number: Silicone oil

- Color: Transparent

- Chemical Name: polydimethylsiloxane silicone oil

- Viscosity: 50cst 100cst 350cst 500cst 1000cst

- Density: 0.97 g/cm3

- Function: Demoulding

- Package: 1000 kg / Drum

- Shelf life: 12 Months

Usage

Water proof gypsum board production, Electronics Chemicals, Leather Auxiliary Agents, Paper Chemicals, Petroleum Additives, Plastic Auxiliary Agents, Rubber Auxiliary Agents, Textile Auxiliary Agents, Water Treatment Chemicals, De-molding

Classification

- Chemical Auxiliary Agent, Chemical Auxiliary Agent

- CAS No.: 9006-65-9

- Other Names: PDMS

- MF: C6H18OSI2

- Purity: 100%

- Place of Origin: Hebei, China

- Type: Adsorbent

- Adsorbent Variety: Silica Gel

Features

Vinyl silicone oil is vinyl-terminated dimethylpolysiloxanes and has a reactive vinyl group. They can be used as base polymers of silicone rubber or as blend polymers in order to create the desired hardness. These polymers can be cured with silicon-hydride crosslinkers and a platinum catalyst.

Note

- This product is not too dangerous, but not to eat and enter eyes.

- This product is non-toxic, has good physiological inertia, no irritation and damage to the skin. Products do not contain flammable and explosive ingredients.

- It will not cause fire and explosion accidents and has no special requirements for transportation.

- This product is not suitable for long-term use at a high temperature above 250 ℃, but can be used continuously at – 60 ~200 ℃.

Applications: Used as base polymers

|

Item |

Technical Data |

|

Appearance |

Colorless transparent fluid |

|

Volatile Matter(%) |

≤1.0 |

|

Viscosity (cps, 25℃) |

300-100000 |

|

Vinyl Content(%) |

0.08-1.40 |